MBI Long format facing brick GeoStylistix: 'Creating cool buildings together'

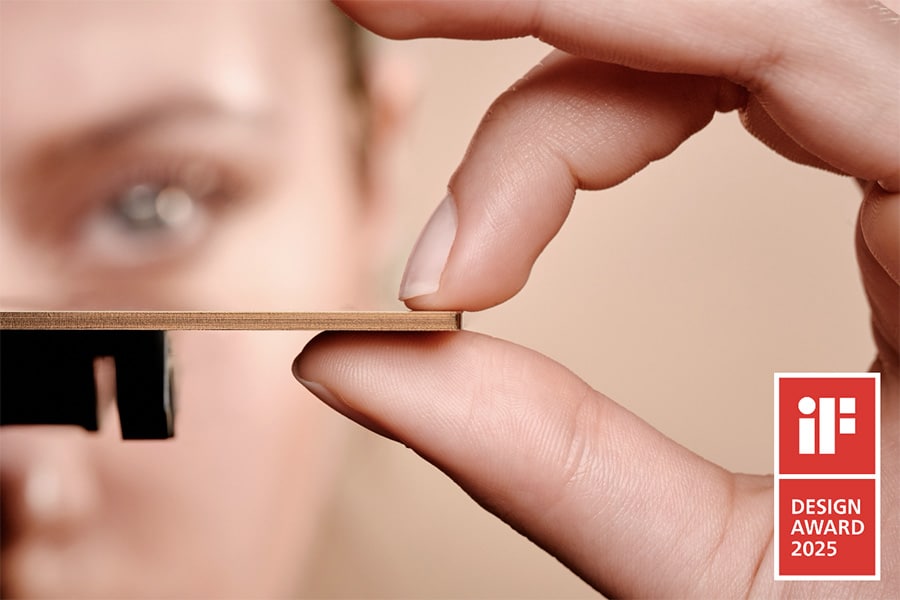

Extra slim, with a smooth top layer of crushed natural stone and available in a variety of colors. It characterizes GeoStylistix, an a-typical long-form facade brick, based on a base of concrete. Consultant Michael den Breems of MBI: "Architects who see this stone for the first time are wildly enthusiastic. It is a modern stone, in contemporary material, dimensionally stable and super sleek."

MBI is the inventor of concrete bricks with a colorfast coating. These have already been successfully used in the Dutch streetscape since the 1980s. "We translated this technique seven years ago to the production of facing bricks, where the concrete base is coated with a top layer of natural stone granulate. For an extra special effect, we chose a long-format brick, this is GeoStylistix." The top layer contains only colorfast materials, such as Norwegian marble or basalt-colored rock. Due to its success, this stone is now also available in a waal format.

Architects are very fond of the format, according to Michael. "The Netherlands loves masonry facades, however, the most commonly used format is waal format. Our brick is almost three times as long; 60 cm wide and 4 cm high. That is gives a very unique look." Its size and dimensional stability make it great for bricklaying, but also for gluing. Architects who first encounter this brick qualify it as very modern; contemporary, dimensionally stable, slim and sleek."

In the production process, the bricks gain ultimate strength in four weeks. "After production, we remove them from the mold and let them harden in the climate chamber for 24 hours. We continue that process in the open air. The stone is composed of a strong concrete backing with a top layer of natural aggregates. To the concrete base we add a large percentage of secondary raw materials such as residual products. This gives the brick an interesting MKI value; the environmental cost indicator that shows what footprint a brick leaves behind. Our footprint is incredibly low because in addition to sustainable raw materials, little energy is consumed. By comparison; a brick obtains its hardness by being fired at a very high temperature while the concrete brick hardens in the open air."

Twelve colors in stock

Michael: "We make different sizes of GeoStylistix in our factories; long- and waal format, as well as an intermediate size. The sleek, even stone is the most commonly used. However, there is also a demand for a long format stone that has more relief. For this reason, we have acquired a new mold with which we press the top layer and give the bricks organic shapes.

We stock GeoStylistix in twelve colors. If the color you require is not among them, we can produce and deliver a custom color for a modest additional charge. Of course, a minimum project size then applies. "We know that architects are very visionary and sometimes have to deal with specific environmental factors in the design. We then like to think along with them. Together we realize cool buildings."