More efficient insulation during prefab modular construction

Glass wool, a durable and safe choice in frame structures

Prefabricated modular construction with timber and steel framed buildings has been on the rise for some time now, and FRAMETEC is cleverly capitalizing on this. The newest member of the URSA TERRA glass wool family scores in terms of both ease of installation and sustainability. With more square meters of glass wool per pallet, reduced transport and CO2 emissions, space savings in the warehouse and on the building site, and time and efficiency gains for the installer, FRAMETEC offers many advantages at every stage of the construction process.

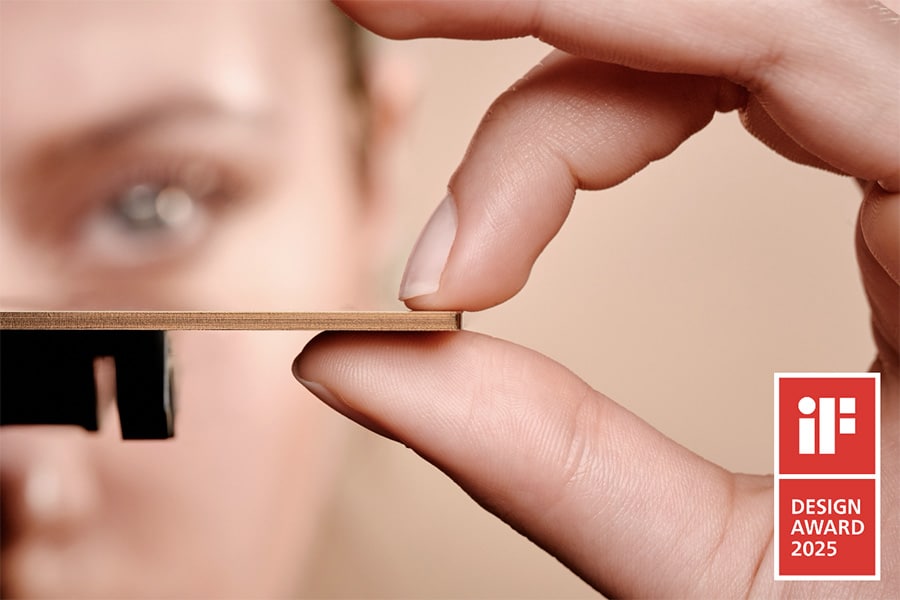

That prefab modular construction is gaining momentum in the construction industry should come as no surprise. Meticulous preparation in the workshop significantly shortens the building process and construction time on site, regardless of weather conditions. At the same time, this approach minimizes back-and-forth transportation and inconvenience to local residents. Mineral glass wool fits perfectly into this picture and is increasingly used in renovation, new construction, timber and steel frame construction, and pitched roofs. Consequently, the versatile URSA TERRA insulation material offers numerous advantages in frame construction: durability, efficiency, quality and safety. For example, URSA glass wool products are completely fireproof and 100 percent recyclable. They are also known for their excellent thermal and acoustic performance, guaranteeing optimal living comfort in the home. URSA TERRA glass wool is very quick and easy to install. Moreover, because the product adapts itself, you have no seams, making it a popular solution with many contractors and installers.

Optimized lengths for precast

In 2024, the company is focusing more than ever on lightweight, modular precast construction. From its investments in the future and continuous improvement of URSA TERRA technology, the manufacturer is launching FRAMETEC: an insulation product specifically aimed at wood and steel construction within the precast market. The new insulation product continues the line of circular construction while capitalizing on ease of use and installation. The glass wool is produced with recycled glass and sand, and is fully processable so there is no waste in the production process. Like all products within the URSA TERRA family, FRAMETEC is extremely soft and virtually no dust is released during installation.

Unroll, install and ready. It's that easy to install FRAMETEC on your project. In fact, the range includes optimized roll lengths and additional sizes: FRAMETEC 32, 35, 37 and 38. This means more insulation is packed into one roll, which translates into more square meters of glass wool per pallet, less transportation and CO2 emissions, and space savings in the warehouse and on the job site. In addition, you need fewer rolls of insulation for the same project. Moreover, due to the dimensional design, cutting losses remain minimal. Thus, FRAMETEC leads to time and efficiency gains in the field. This applies to both installers of prefab in timber and steel construction, tiny house builders and traditional timber frame builders who insulate on site.

Shortened construction process

By focusing on modular construction, partner STiDO from Asse succeeds in reducing the lead time of its construction projects to about twelve weeks. The use of FRAMETEC plays an important role in this. For example, the glass wool offers excellent clamping force, ensuring that the material is clamped firmly, seamlessly and securely between the wooden battens. This makes FRAMETEC highly effective in insulating walls, roofs and floors in wood frame structures. This results in modern structures with low environmental impact and healthy, safe living conditions. Finally, the partner finds URSA's flexibility to develop customized solutions an additional asset.