Retaining value of floors, how do you do it?

Unique in the linoleum world

When building and renovating, sustainability is becoming increasingly important. Where do products come from? What is their environmental impact, and what happens after their initial lifespan? These are questions that Forbo Flooring has been addressing for years. The company's most recent development is Marmoleum Walton Circular, a linoleum floor that incorporates reclaimed previously installed material.

Forbo Flooring designs flooring solutions with a better future in mind. This makes the company the ideal partner for architects in making sustainable choices. "We see architects as champions and inspirers in the field of sustainable building and renovation," says Hanne van Nederveen, segment manager architecture and design. "This aligns with our principles when we design floors: reuse and value preservation. We want to minimize our carbon footprint, by maximizing reuse of renewable and responsible raw materials."

With this in mind, Forbo Flooring is happy to advise architects on a sustainable, safe and circular flooring solution for any project. The company can substantiate the properties of the floors with third-party verified EPDs (Environmental Product Declaration) and HPDs (health product declarations).

One of the innovative and sustainable options is a Modul'Up loose lay floor, which is installed without glue. This sheet vinyl is also easy to disassemble and reuse without modification. In addition, Forbo can recycle it in its own process to serve as recycled content for other vinyl products

In addition, Marmoleum is obviously a sustainable choice simply because of the natural raw materials used to produce the linoleum. Moreover, cutting remnants left over during the production process are made into a raw material again. At the beginning of 2000, Forbo expanded the recycling flow to a service where customers can also return the cutting remnants of newly laid floors for recycling.

Innovation: Marmoleum Walton Circular

Van Nederveen: "We recently took this one step further: by taking back and recycling linoleum floors that have been in service for years. Recycling a used floor that has been walked on, tampered with and has glue residue stuck to it is quite a challenge. A challenge we were happy to take on."

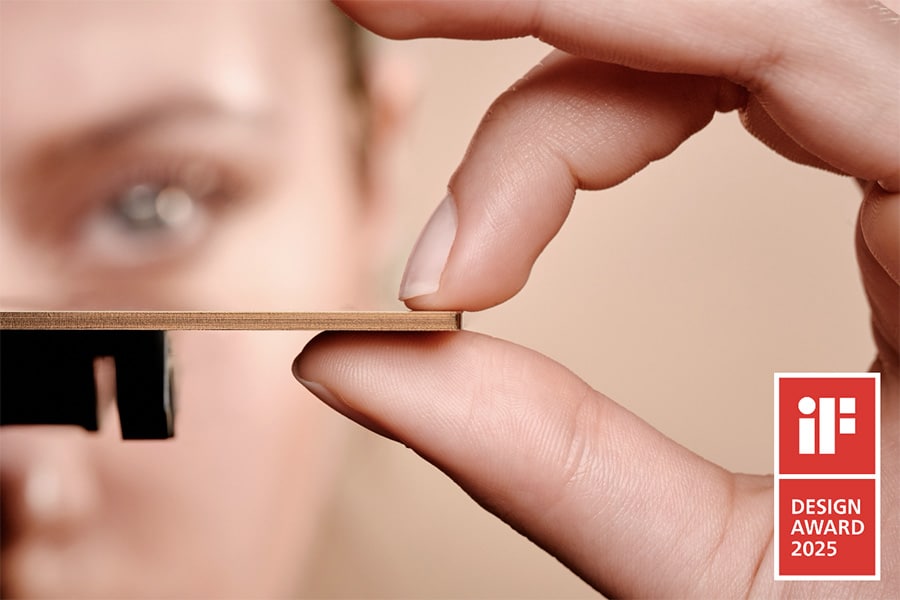

Forbo Flooring supported TU Delft in the renovation of the Faculty of Electrical Engineering Mathematics and Computer Science. The faculty's 20-year-old Marmoleum floors were completely recycled. "We managed to process reclaimed material in our own production into 'new' linoleum: Marmoleum Walton Circular. In this there is not only post-use (end of life) recycled content in the backing of the product, but for the first time it is also recycled in the top layer. A one-of-a-kind product!"

This superlative in Forbo's sustainable story is certainly not a one-off. The company is seeking collaboration with architects to spot renovation projects early on, so that it can take back used flooring for incorporation into new flooring. "It is necessary to keep talking to each other, because you cannot do circular work alone. Thanks to architects, we can find old biobased floors from which we can make a new floor. In effect, the floor gets a second life, and the value is preserved."

On display at Architect@Work was the Marmoleum Walton Circular, but visitors could also win 100m2 of the floor.