More opportunities, less impact

Create large glass areas with circular and easy-to-process curtain wall system

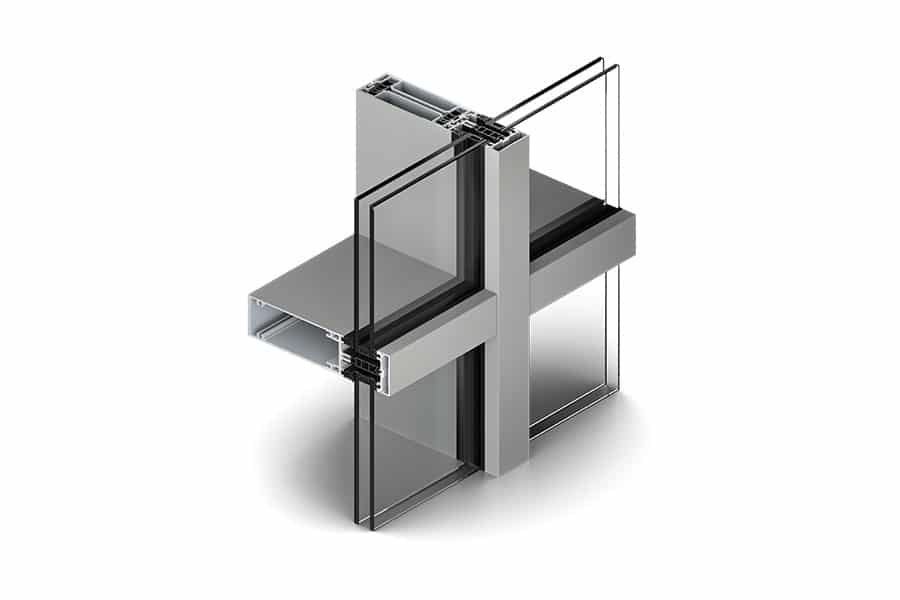

Architects and contractors are increasingly opting for large glass sections with slim profiles, in order to let in as much daylight as possible and guarantee maximum transparency. In addition, they value thermal insulation, sustainability and circularity. SAPA combines all these themes in its innovative and modular facade concept TENTAL, which is produced from Hydro CIRCAL 75R post-consumed aluminum with an extremely low CO2 footprint.

TENTAL gives architects and consultants the creative freedom to design the facade they actually envision, says Marc van den Nieuwenhof, Area Manager at SAPA. "Our curtain wall system is available with 50 and 60 mm wide aluminum profiles, for the design of contemporary modular facades with large glazing units. The modules can feature panels weighing up to 850 kg and covering an area of up to 12.25 m, depending on the type of glass used."

Concealed inward and outward opening windows were designed specifically for TENTAL. "There is also a wide range of cover caps to choose from, from standard cover caps to semi-cover caps that emphasize the horizontal lines of the rails or vertical lines of the stiles. In addition, flat cover caps are possible for a smooth appearance of the profiles and glazing," says Alex Caestecker, Project Manager at SAPA. "Different assembly technologies, colors and textures and hidden drainage complete the architectural quality and freedom. Moreover, TENTAL is compatible with a full range of SAPA windows, doors and sliding doors, such as our new window and door system SOLEAL NEXT or the well-known Avantis Smartline."

Extensive architectural guidance

Caestecker is new to the sales team of SAPA Netherlands and, together with Van den Nieuwenhof, will provide architectural guidance. For example, in choosing the optimal aluminum profile system for their projects. "We inform architects our about (new) products and the circularity ambition of the Hydro Group," he says. "We also support the dimensioning of the profiles, the specifications and provide the right samples. If required, we can even support the presentation and justification to the client. For example, with regard to the TENTAL curtain wall system, which is currently being rolled out in the market."

High performance, easy processability

TENTAL modules can integrate double or triple glazing up to a maximum thickness of 62 mm, resulting in excellent thermal, acoustic and watertight performance. As an example, Caestecker cites the unique performance of TENTAL 50: water tightness up to RE 1500 Pa, wind resistance up to 2000 Pa, air tightness up to AE 1500 Pa, burglar resistance classes RC2 and RC3, thermal insulation Ucw up to 1.4 W/m²K and acoustic insulation

Rw (C;Ctr) of 43 (-1;-3) dB.

"This performance is already an important asset, but with TENTAL we also offer in addition a very an easy-to-process facade solution," adds Van den Nieuwenhof. "During development, our R&D department explicitly looked at how they could facilitate and speed up the work of the processor. For example, if required, facade builders can build their battens and posts with the same profile, reducing sawing residues to a minimum. This is interesting, for example, in smaller projects. The windows can also be assembled in advance, after which the cover strips follow later. Without the need for temporary clamping in between. This takes a complete work step out of the process. The installation of the glazing rubbers is carried out dry, without the use of glue or sealant. This makes disassembly, reuse and recycling easier over time."

Minimum 75% post-consumer scrap

"Underlying the TENTAL 50 and 60 profiles is the Hydro CIRCAL 75R alloy, which incorporates at least 75% post-consumer scrap and has a CO2 footprint of only 1.9 kg CO2 per kg aluminum," Van den Nieuwenhof explains. "Post-consumer scrap mainly includes old windows, doors and facade systems that have reached the end of their technical lifespan. The aluminum spread across two production sites in Europe fragmented, sorted and processed/melted into a new alloy for the production of new aluminum building systems. Without sacrificing quality and material properties." Hydro CIRCAL 100R, which has a CO2 footprint of less than 0.5 kg CO2, is now also available on request.

Aluminum can be used endlessly, without loss of quality and properties, he stresses. "Thanks to the revolutionary treatment of delivered scrap, the quality of this material is quasi-identical to that of primary aluminum."