Cementitious screed system gives showroom and office space unique look

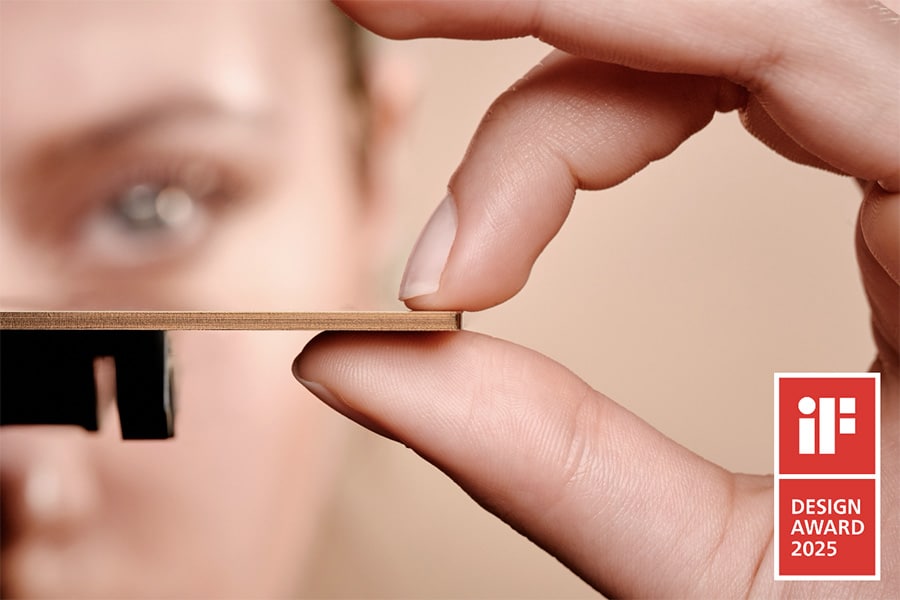

The premium designed rooms with natural colors called for a representative flooring design concept, which was found in Arturo Concreta. This 2-component floor finish combines a high degree of functionality with a natural appearance. Thanks to manual processing, a particularly variegated and slightly structured surface was created: seamless, low-maintenance, liquid-proof and with a unique design.

"The high-quality appearance and natural ingredients of Arturo Concreta perfectly match the inspiring atmosphere of the showroom and office space," says key account manager Stefan Dröge. "The 2-component floor finish consists of natural cementitious components such as sand, cement, color pigment and water and is applied in multiple layers. The flooring system is low-emission and UV-stable, which is very important for facades with large window areas. When applied, the floor creates a surface texture with a light tint that gives the floor its own natural look."

Warm, natural hue

Arturo Concreta is available in ten natural colors, from warm beige, gray and brown to bold anthracite. In this project, the warm, natural shade Fossil was chosen. "Before applying the screed, the substrate must be carefully prepared," emphasizes Ejup Hasanovic, who was responsible for the implementation with his company Natura Bodendesign. "It must be solid, dry, clean and absolutely even, without unevenness, cracks or dust residue. Only then will the surface and appearance come out at their best." Therefore, the applicators in the Watermark Tower first applied a leveling to the substrate. After sanding, vacuuming and applying a primer, a scraper coat was applied to the floor to eliminate slight unevenness. The scraper layer was sanded off with a quartz sand (grain size: 0.3-0.8 mm), which ensures optimal adhesion of the coating.

Application of screed

At an optimal floor and ambient temperature of approx. 20°C and an ideal humidity of approx. 65%, application of the screed can be started. For this purpose, first the prescribed amount of water and selected color pigments are mixed. Then the Concreta cement mix is added and mixed into a homogeneous mass, which is distributed over the floor. This creates the unique look with vibrant colors and smudge effects. After curing, the ambient temperature is measured again and the impregnator is applied crosswise. This ensures optimal adhesion and processing of the sealing top coat, Dröge said. "The transparent 2-component topcoat is applied in two coats and gives the floor not only additional protection, but also the desired matte look."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Arturo Flooring.

Contact opnemen

Contact opnemen